|

Nitreg®

Potential-Controlled Gas Nitriding

- Nitreg® -氮势 – 可控氮化

亲爱的访问者,

在您探访本站之前, 请注意该部分网页内容正在建造中.

对由此引起您的不便我们真诚表达歉意.

请在英文网页继续您的浏览. 如果无法找到您需要的信息请与我们联系.

What is nitriding?

Before a specific explanation of Nitreg® can be effectively presented, as well

as for the sake of completeness, we will describe nitriding in general. Then we

will proceed to describe our “potential-control” group of technologies.

Nitriding is a process of diffusing nitrogen atoms into the metal’s surface.

Nitrogen is plentiful on Earth, however, in nature it exists as a two-atom

molecule, chemically inert and too large to penetrate the surface. Hence

nitriding technologies focus on the source of nascent (atomic) nitrogen.

Regardless of the method, nitriding is

a process of diffusing nitrogen into the metal and such diffusion, once

individual atoms of nitrogen have penetrated the surface, continues as long as

the temperature is high enough, and there is a fresh supply of nascent nitrogen

on the surface. In other words, the diffusion is basically the same in all

nitriding, while the difference lies in the supply of nitrogen. The latter has a

fundamental influence on the resultant properties of the surface.

Traditional Nitriding Methods

The three traditional nitriding

methods practiced on an industrial scale are:

(a) salt bath (liquid) nitriding,

where the source of nitrogen (and also carbon) is molten salt,

(b) gas nitriding which uses ammonia

(NH3), and

(c) plasma nitriding where molecular

nitrogen (N2) is split into ions in an electromagnetic field.

Salt baths are not used by Nitrex due to that method’s environmental dangers and

our concern for personal safety of the operators. Besides, the process has few

advantages, quick heating of the workpiece being the only one worth mentioning.

Therefore the process shall not be described any further.

Plasma nitriding is used by Nitrex for selected applications and the process is

described as a

separate paragraph in the “Technology” section.

Nascent nitrogen is obtained from ammonia in gas nitriding. The conventional

version of the process relies on the measurement of the dissociation rate of

ammonia into its constituent gases – nitrogen and hydrogen. A simple device

called a buret (or more properly burette) is employed for periodically checking

the dissociation rate and an adjustment to the flow of ammonia is made as

required, usually in a manual fashion.

Materials

Generally speaking all ferrous alloys,

including stainless steels, cast irons, and even titanium alloys, are capable of

being nitrided. However, the various alloys have different characteristics with

regard to surface conditions, the natural speed of diffusion and propensity to

form nitrides. It is important to understand that even a properly run nitriding

process will produce significantly different results on dissimilar materials.

Consequently, some users may have insurmountable difficulties, particularly if

their methodology is primitive and/or their knowledge and experience inadequate.

Nitriding Effect - Properties of

Nitrided Layers

A surface exposed to a nitriding medium will generally form two distinct layers.

The outside layer is called a compound layer (or white layer) and its thickness

generally falls between zero and 0.001” (25

mm). Underneath the white layer we have a diffusion case or diffusion

zone. Both together comprise what is generally referred to as the case. However,

as mentioned earlier, depending on the material and its original pre-process

hardness there will be very significant differences between the properties of

these layers. A full description of these phenomena is well outside the scope of

this website. We encourage our visitors to contact us if specific such

information is required. Meanwhile we will concentrate our attention on

explaining the “why and how” of controlling the properties of the nitrided

surface, particularly with regard to the compound layer.

Control

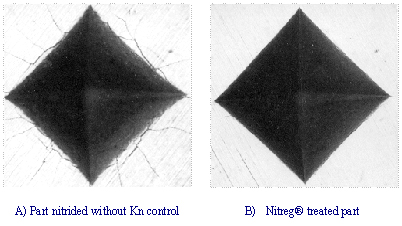

The images of two Vickers hardness

tester indentations shown below illustrate the difference between a controlled

and uncontrolled process. The specimen on the left was produced in a traditional

process and the cracking of the surface is indicative of the brittleness of the

layer. The one on the right is a product of a Nitreg® process where, in spite of

the same hardness, cracks have not formed. The Nitreg® treated component is

therefore more resilient with high toughness of the compound layer.

Such superior result can only be

achieved by controlling the nitrogen concentration in the substrate and the

modern approach is control of nitriding potential (Kn). Proper understanding and

application of the principles that tie nitriding potential (Kn), temperature and

time are the cornerstone of the Nitreg® technology. An example of our ability to

produce a variety of white layer / diffusion case combinations is shown in the

following chart:

Nitrided case combinations -

Acrobat®

Gradually the ability to control the

nitriding potential is becoming a requirement as set forth by specifications

such as AMS 2759/10.

In

conclusion, Nitreg® is a modern process, capable of meeting the metallurgical

requirements of all nitriding specifications that may have been originally

written for salt bath, plasma or traditional gas nitriding

|